-

Jas Boutique

Adrianna Large Contemporary Hand Blown Glass Art Chandelier - Clear Glass Murano Lamp

£6,640.99 -

-

-

Jas Boutique

Clara: Hand Blown Glass Chandelier - Chandelier Murano Glass - Artistic Glass Chandeliers

£21,999.99 -

-

-

Jas Boutique

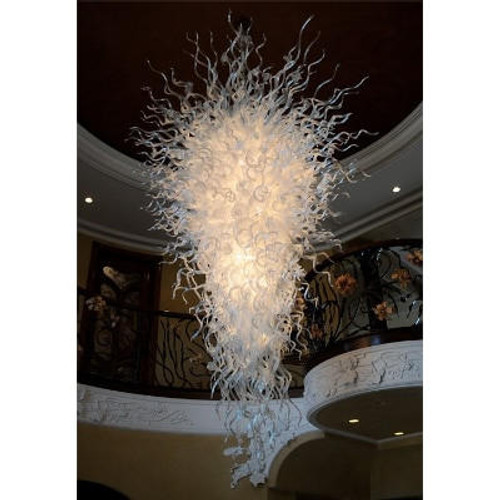

Elisa White Unique Murano Hand Blown Glass Vertical Chandelier - Large Modern Chandeliers For High Ceilings

Was: £9,699.99Now: £8,899.99 -

-

-

-

Jas Boutique

Cobalt Blue Glass Chandelier Murano - Large Blue Glass Pendant Lights - Venetian Blue Lamps

£6,290.99 -

Murano Hand Blown Glass Chandeliers

What is Murano Glass?

Murano glass is a type of glass renowned for its exceptional quality, craftsmanship, and rich history. It takes its name from the small island of Murano in the Venetian lagoon, near Venice, Italy. Murano glass has been produced on this island for centuries, and its origins can be traced back to the 13th century.

What sets Italian Murano glass lighting apart is the skill and artistry of the glassmakers who craft it. These artisans, known as maestri vetrai, have honed their craft through generations of family traditions and have mastered the techniques that make Murano glass so unique.

The techniques used to create murano glass lighting pendants are diverse and require a high level of precision and expertise. Some of the most common techniques include:

1. Murrine: This technique involves layering and fusing together thin glass rods of different colors, creating intricate patterns that are visible when the glass is cut or shaped.

2. Filigree: Delicate glass threads, known as filigrana, are twisted and intertwined to form intricate designs. The resulting glasswork has a lace-like appearance.

3. Sommerso: This technique involves encasing one layer of colored glass within another, creating a layered effect and adding depth to the final piece.

4. Latticino: Thin glass canes of different colors are combined and twisted together, resulting in a striped or twisted pattern.

5. Avventurina: This technique incorporates the use of copper or gold particles in the molten glass, creating a sparkling, metallic effect.

Italian Murano glass is known for its vibrant colors, intricate patterns, and exceptional clarity. The maestri vetrai have perfected the art of manipulating molten glass, allowing them to create a wide range of shapes and forms, including vases, sculptures, chandeliers, and jewellery.

The glassmaking tradition in Murano is not just about craftsmanship; it is also deeply rooted in innovation and experimentation. Throughout history, Murano glassmakers have pushed the boundaries of glass artistry, developing new techniques and constantly refining their skills.

Today, Murano hand blown glass is celebrated worldwide for its beauty and artistry. It has become synonymous with luxury, elegance, and unparalleled craftsmanship. Owning a piece of Murano glass is not just owning an exquisite work of art, but also owning a piece of history and tradition that has been passed down through generations of skilled artisans.

Glassblowing: A Process of ‘Happy Accidents’

Glassblowing has been a process of ‘happy accidents’ from the time it was rumored to be discovered by shipwrecked Phoenician sailors around 23-79 A.D. along the Mediterranean coastline that stretches across present-day Syria. The sailors started fires on the beach that exceeded 1800° C -- hot enough to fuse the grains of sand into silica glass.

That knowledge made its way to Europe and the craft of glassblowing was formalized in 1st Century B.C. in Cologne, Germany and some would say the craft was perfected by the Venetians during the Renaissance period. Since then, the delicate art of glassblowing has come in and out of vogue throughout the centuries.

Modern Day Glass Blowing

Tradecraft is making a comeback in a big way with an increasing number of young people studying to be butchers, woodworkers, and bakers: old world crafts that were phased out by machines are now coming back in style with a focus on “small batch” and “handcrafted” items.

Glass artists, such as Seattle-based Dale Chihuly, gained notoriety in the late ‘80s and ‘90s and created a renewed interest and Renaissance of sorts for glassblowing. If you run a quick search online today, you are likely to find dozens of glassblowing classes and courses offered at local studios if you live in a metropolitan area.

Visiting a Glassblowing Studio: What To Expect

If you are considering learning the craft of glassblowing, what can you expect from your first visit to a studio? Expect the glassblowing studio to be hot. Exceptionally hot. The furnace you will be working with exceeds 1,320° C.

Tips for first-time visits to a glass studio:

-

Do not stand in front of the furnace longer than necessary. The heat is intense and prolonged exposure, especially without tolerance, could make you lightheaded.

-

Hydrate before your class and bring a large water bottle so you can stay hydrated throughout a long, hot lesson.

-

You will be working with molten glass so it is very important to keep your skin covered. Given the extreme temperatures, opt for lighter fabrics such as a long-sleeved cotton shirt. Avoid synthetic fabrics that are prone to melting in high heat.

-

Similarly, it is important to wear closed-toed, durable, slip-resistant shoes. Other classmates may unintentionally spill graphite powder and you don’t want to slip while holding “cool” glass -- cool glass is still 482° C!

-

If you have long hair, keep it tied back and tucked away.

-

It’s important to wear protective eye gear, but sunglasses would also be helpful for your time spent in front of the furnace.

Glassblowing Equipment and Terminology

Like many other crafts, glassblowing comes with a specific toolset and terminology that you will have to learn in order to become a master.

-

Gaffer: The lead glassblower. While glassblowing can be done individually, it’s such a challenging process that it is often done with an assistant or even a team of assistants.

-

Glory Hole: The casual term used to reference the furnace.

-

Blowpipe: An iron or steel pipe that measures roughly 1.2 meters in length, used to blow air from the gaffer’s mouth into the ball of glass to begin creating a bubble.

-

Gathering Iron: An iron rod used to gather molten glass after it has been brought out of the furnace.

-

Marver: A large flat surface used to roll and shape the glass.

-

Block: A wetted wooden shaping tool, as is a bladed tool called a jack.

-

Paddle: A tool that is used to smooth out the glass and sometimes to shield the gaffer from the extreme heat of the glory hole.

-

Tweezers: Another useful tool for grabbing and manipulating hot glass.

-

Parison: Term for partially blown glass.

-

Punty: A smaller metal rod often used to add bits of glass to the parison (as various colorants).

-

Threads and Wraps: Terms used to describe the stretched parison that is used to create decorative patterns on the glass object being created.

-

Pontil: Another metal rod and tool that is attached to the base of the blown glass to hold it while the mouth end is being shaped. The mark that the pontil leaves in the parison is typically polished off later.

-

Yokes: Metal stands inside the glory hole where the partially blown glass rests until it is hot enough to continue the process.

-

Annealer or Lehr: A specific furnace that controls the rate of cooling to keep the finished piece from cracking.

-

Pyrometer: Measures the temperature during the annealing process to ensure that the glass is brought below the point of softening.

-

Cold Shop: Term used to describe a studio apart from the glass blowing studio (without furnaces) where it is ground, polished, engraved, or enameled.

Glassblowing: Step-by-Step

About the Sand

Glass is a solid and yet it’s transparent. This is due to the unique molecular structure of glass which makes it more similar to a liquid than a solid. It is this unique molecular structure that allows for glass to be blown into shapes like bubbles, yet molded like clay.

Most of the glass that you will encounter is an oxide glass and the base is silica (silicon dioxide) or sand. This isn’t Syria in 23 A.D., so the sand being used is no longer the sand you pick up by the bucketful at the beach. Rather it’s a sand that has been cleaned of impurities or contaminants, to increase the control that the gaffer has over the glassblowing process.

The sand is mixed with fluxes, which lower the melting point of the sand and increase the flow rate of the glass mixture. Fluxes include alumina, zinc oxide, barium oxide, and lithium. Once the glass is mixed into batches, you’re ready to begin.

Charging the Batches

The gaffer, or the assistants, will place a batch inside a pot inside of the glory hole. In a process called charging, these batches melt at 1,100° C. The gaffer will reach for his blowpipe and dip it into one of the charged batches. The gaffer constantly spins the blowpipe in a controlled manner and the glass is secured to the end. The opposite end of the blowpipe, where the gaffer will blow, is cooled off in a barrel of water.

Blowing Glass

When the blowpipe has been sufficiently cooled, the gaffer will blow through the tube and create a bubble in the glass secured at the opposite end. Whenever he is not blowing, the end of the tube is capped so the hot air remains trapped in the glass, maintaining its shape.

It is important not to inhale when your lips are on the blowpipe during the process of glassblowing. The air inside is heated at several hundred degrees and while the length of the pipe might allow it to cool to a more tolerable temperature before it reaches your lips, it’s better to be cautious.

When observing the gaffer in a glassblowing class, pay close attention to where he places his hands are on the blowpipe. Glass blowing is about control and proper hand placement on the blowpipe is key to maintaining balance and control over your piece.

More layers of glass are sometimes added with the gathering iron, or by dipping the glass that is attached to the blowpipe back into the batch. Gaffers will often make several trips to the glory hole to add glass and maintain the heat while they work.

Coloring and Shaping Molten Glass

To add color, the parison is spun constantly by the gaffer while he or an assistant add bits of glass with the punty to add color. The gaffer will use a marver, block, bladed jack, or paddles to roll and shape the glass into its desired form. Tweezers are used for more detailed work and to manipulate smaller glass pieces. Glass threads and wraps are added from the batches to create patterns if desired.

Transferring the Parison to the Punty

One of the main reasons why glassblowing is often done by a team of people is because of the transfer to the punty. The parison will be transferred to the same rod that was used to strategically add color to the form.

Oftentimes an assistant will gather a small bit of clear glass from a batch in the glory hole. The assistant will approach the gaffer, who is usually seated and constantly turning the parison, who will stop turning the piece while the assistant attaches the punty with the molten glass at the opposite end.

The gaffer then taps the blowpipe and it breaks away, leaving the parison attached to the punty. If the glass is dropped during this process, as often happens with novices, the piece has to be recreated from scratch. There is no salvage.

Opening the Parison

The gaffer takes the punty and once again returns it to the heat of the glory hole. Afterward, a variety of tools are used to gently create the mouth of the vase or bowl that is being created. Once the gaffer is satisfied it is time to cool the piece.

Using the Annealing Furnace to Cool

As discussed in “tools and terms” earlier, the annealing furnace or lehr is used for controlled cooling of the glass piece to keep it from cracking while it returns to its solid form. The temperature in the lehr does not exceed 516° C and from there the piece is cooled very slowly and gently over a period of 14 hours until the glass finally reaches room temperature. After this point the glass is taken to the “cold shop” to be polished and have the final decorative details added if necessary.

If you’re considering learning how to blow glass, remember that it takes time, dexterity, and a lot of patience -- especially when learning -- to master this ancient craft.

Murano glass chandeliers Venice Italy

Murano hand blown glass chandeliers are some of the most beautiful and luxurious lighting fixtures in the world. The term murano chandeliers originate on the Venetian island of Murano, which has been known for its glassmaking since the 13th century. Murano glass is renowned for its unique and intricate designs, as well as its vibrant colors and unparalleled quality.

Murano glass chandeliers are handcrafted by skilled artisans who have spent years mastering their craft. Each chandelier is made from start to finish by hand, using traditional techniques that have been passed down for generations. The process of making a Murano glass chandelier is complex and involves many steps, including blowing the glass, shaping it, and assembling the chandelier.

One of the most distinctive features of a Murano venetian crystal chandelier is the use of colorful glass. Murano glassmakers are famous for their ability to create glass in a wide range of colors, from bright and bold to subtle and muted. This allows for endless possibilities when it comes to designing and creating contemporary murano glass lighting that is truly unique and beautiful.

Another defining characteristic of Murano glass chandeliers is the intricate and detailed designs that are incorporated into each piece. Many Murano chandeliers feature intricate patterns and designs that are etched or carved into the glass, creating a stunning visual effect when illuminated. This attention to detail and dedication to craftsmanship is what sets Murano glass chandeliers apart from other lighting fixtures.

Murano glass factory chandeliers come in a wide range of styles and sizes, making them suitable for any space, from grand ballrooms to small dining rooms. They can be customized to meet the specific needs and tastes of each customer, from the color and design of the glass to the overall shape and size of the chandelier.

In addition to their beauty and craftsmanship, Murano glass chandeliers are also incredibly durable and long-lasting. Unlike other lighting fixtures, which may need to be replaced every few years, a Murano glass chandelier can last for decades with proper care and maintenance.

Overall, Murano hand blown glass chandeliers are a stunning and luxurious addition to any space. They are works of art that are created by skilled artisans who are dedicated to their craft, and they offer a unique and beautiful way to light up any room. Whether you are looking for a classic and elegant chandelier or something more modern and bold, a Murano glass chandelier is sure to impress and inspire.

Famous Murano glass chandelier makers

There are several famous Murano chandelier makers that have gained recognition and acclaim worldwide (ourselves excluded from this list as you are already here). Some notable examples include:

1. Rezzonico Chandeliers: These grand, opulent chandeliers are named after the Palazzo Rezzonico in Venice. They feature intricate designs, multiple tiers, and a profusion of glass arms adorned with elaborate glass elements. Rezzonico chandeliers are renowned for their grandeur and are often considered iconic representations of Murano glass craftsmanship.

2. Ca' Rezzonico Chandelier: Located in the Ca' Rezzonico Museum in Venice, this chandelier is an exquisite example of the artistry of Murano glass. It features a stunning design with intricate glasswork and intricate details, showcasing the mastery of the maestri vetrai.

3. Barovier & Toso Chandeliers: Barovier & Toso is one of the oldest and most renowned Murano glass companies. They have created numerous magnificent chandeliers over the years, combining traditional techniques with innovative designs. Their chandeliers are known for their elegance, luxuriousness, and meticulous craftsmanship.

4. Venini Chandeliers: Venini is another distinguished Murano glass company that has produced exceptional chandeliers. Their designs range from classic and elegant to contemporary and avant-garde, showcasing the versatility of Murano glass. Venini chandeliers are characterized by their artistic flair and meticulous attention to detail.

These are just a few examples, and there are many other renowned Murano chandeliers crafted by talented artisans and prestigious glassmaking companies. Each chandelier is a testament to the skill, artistry, and creativity of the maestri vetrai, and they continue to inspire awe and admiration for Murano glass worldwide.

Who invented Murano hand blown chandeliers?

The invention of Murano hand blown chandeliers cannot be attributed to a single individual. Instead, the art of glassmaking in Murano, Italy, has evolved over centuries, with numerous skilled artisans contributing to its development. The glassmakers of Murano have refined their techniques and passed down their knowledge through generations, resulting in the exquisite craftsmanship that is associated with Murano glass today. The island of Murano has been a center of glassmaking since the 13th century, and it has attracted talented artisans who have pushed the boundaries of the craft, creating beautiful murano glass hanging light fixtures and other glass artworks. While specific individuals may have made significant contributions to the art of murano glass lighting pendants, it is the collective effort and expertise of the Murano glassmaking community that has shaped and perfected this unique art form over time.

Where is Murano and what is it history with glass making?

Murano is a small island located in the Venetian Lagoon, just off the coast of Venice, Italy. It has a long and illustrious history with glassmaking, dating back to the 13th century.

The origins of Murano's glassmaking tradition can be traced back to the late 1200s when the Venetian Republic ordered all glass furnaces in Venice to move to Murano due to the risk of fires caused by the furnaces. This move allowed the Venetian authorities to better protect the city's valuable assets and secrets related to glassmaking.

In the following centuries, Murano became a renowned center for glass production, and its artisans began to develop exceptional glassmaking techniques and styles. The glassmakers of Murano were highly skilled and held valuable knowledge, such as the secrets of crystal clear glass production and the creation of intricate patterns.

Murano glassmakers played a crucial role in Europe's Renaissance period, supplying exquisite glassware, chandeliers, mirrors, and other decorative items to noble households and churches across the continent. The glassmakers were also entrusted with creating impressive glass artworks for important events and occasions.

Throughout its history, Murano glassmaking has continued to evolve, with artisans experimenting with new techniques and pushing the boundaries of creativity. The island has been a hub of innovation, producing remarkable glass creations that combine intricate designs, vibrant colors, and exceptional craftsmanship.

Today, Murano remains an important center for glassmaking, attracting visitors from around the world to witness the artistry of the glassblowers and to acquire unique Murano glass pieces. The island is home to numerous glass factories, workshops, and galleries, where visitors can observe the glassmaking process and explore a wide range of stunning glass artworks. Murano's rich history and ongoing contributions to the world of glassmaking have solidified its reputation as a center of excellence in this craft.

Famous Chandeliers

Scotland's historic Dumfries House that Charles, Prince of Wales, restored, features an original large Murano glass chandelier. The magnificent vintage murano chandelier is an example of the artistry and craftsmanship in Murano glass chandeliers venice italy. This exquisite chandelier, likely crafted in the 18th century, showcases the timeless beauty and elegance of murano glass fixtures.

The traditional murano glass chandelier features intricate glasswork with delicate details, showcasing the skill and precision of the Murano glass artisans who created it. Each glass element is hand-blown and shaped with meticulous care, resulting in a stunning display of craftsmanship and artistry.

What sets this antique murano glass chandelier apart is its historical significance and connection to Dumfries House. As part of the restoration project led by Prince Charles, the venetian murano chandelier was meticulously restored and returned to its rightful place in the grandeur of the house. It serves as a testament to the commitment to preserving historical heritage and craftsmanship not only in the house but the italian murano glass pendant lights history and place in it.

The venetian Murano glass chandelier not only illuminates the space with its radiant glow but also serves as a focal point, capturing the attention and admiration of all who enter the room. Its presence adds an air of elegance, sophistication, and regality to the surroundings, enhancing the overall ambiance and beauty of Dumfries House.

This murano glass hanging light fixture represents the rich cultural exchange between Italy and Scotland, showcasing the enduring legacy of authentic murano glass chandeliers and its impact on global artistic heritage. Its restoration and preservation exemplify the dedication to craftsmanship, history, and the arts.

The vintage italian Murano glass chandelier at Dumfries House stands as a testament to the exceptional artistry and timeless beauty of Murano glass, reflecting the Prince of Wales' commitment to historical conservation and the revival of traditional craftsmanship.